bobloadmire

Android Enthusiast

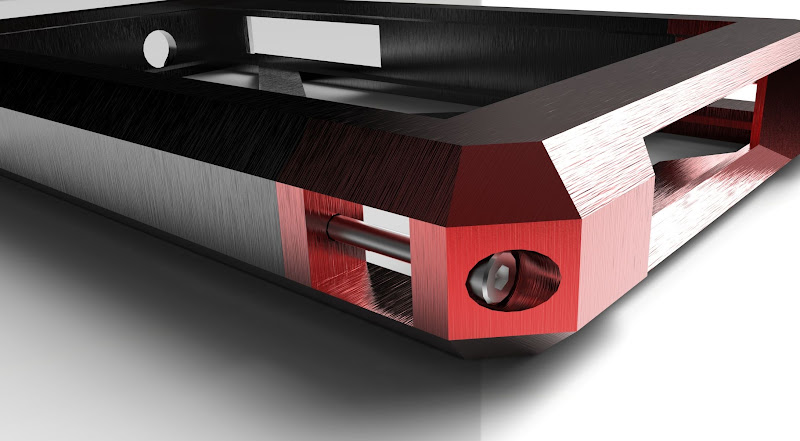

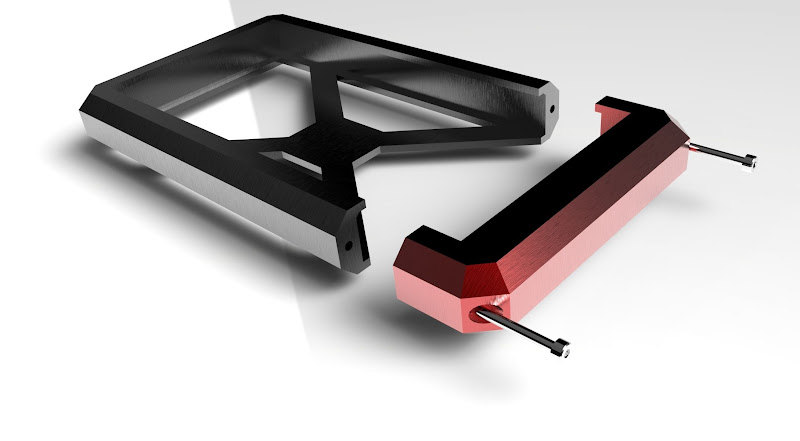

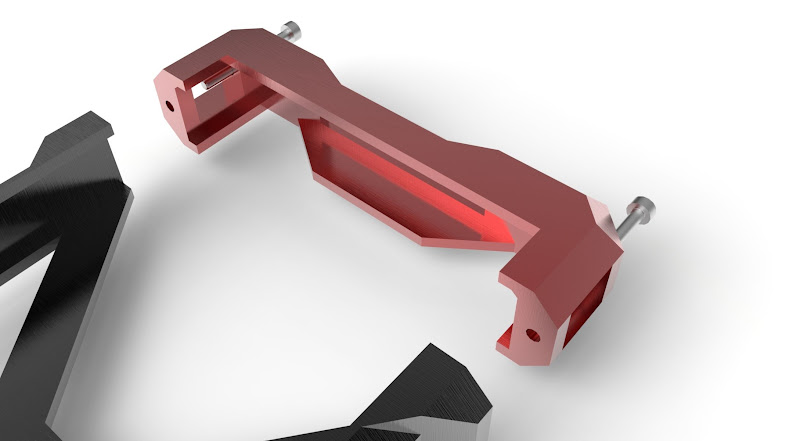

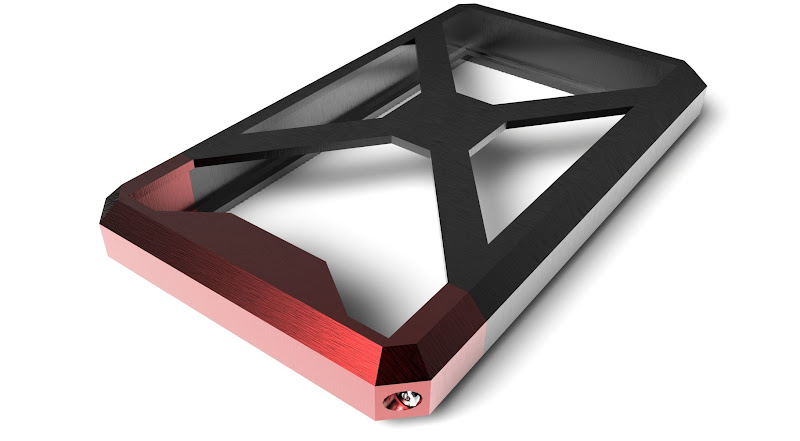

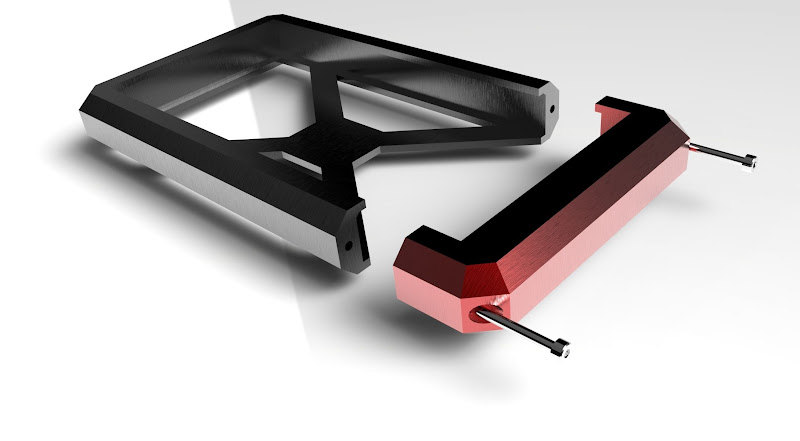

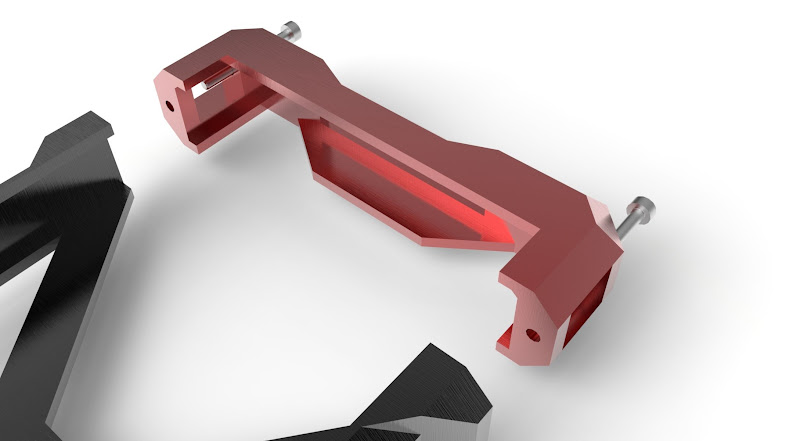

Designed in Solidworks, Rendered in Keyshot. Don't have the money to send off for a prototype, but this would be super nice to have.

Version 1.0

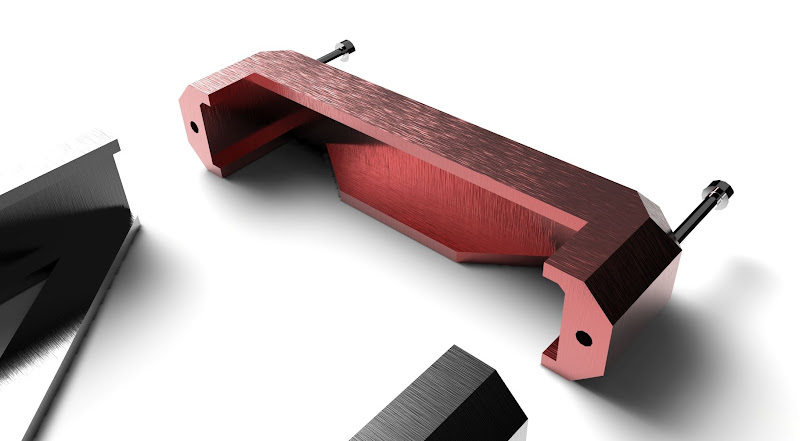

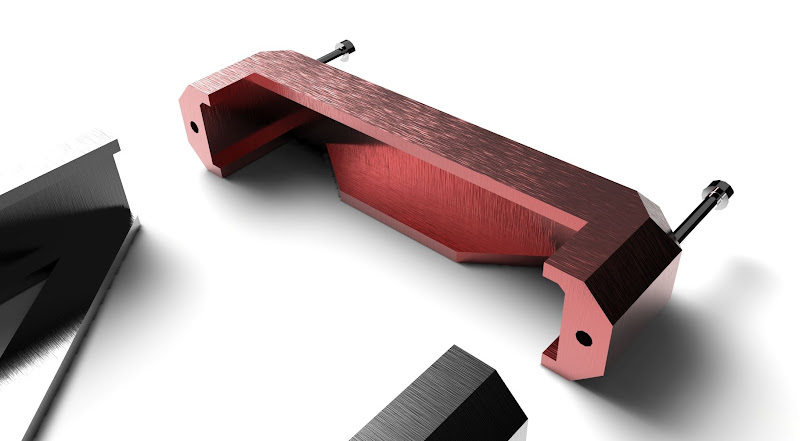

Version 2.0

reduced weight to 20.1 grams and also made thiner and more gripable. Should be easier for headphone jacks too.

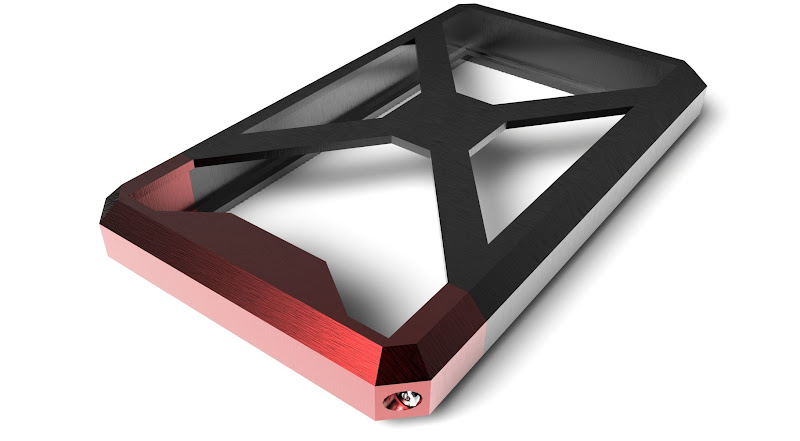

Version 1.0

Version 2.0

reduced weight to 20.1 grams and also made thiner and more gripable. Should be easier for headphone jacks too.

. Too bad I'm not still in school other wise I might've been able to use a cnc mill and cut that out. Or at least make a 3D printing of it... Hmmm... Maybe... Could you pm me the solidworks file?

. Too bad I'm not still in school other wise I might've been able to use a cnc mill and cut that out. Or at least make a 3D printing of it... Hmmm... Maybe... Could you pm me the solidworks file?

just kidding lol

just kidding lol